Floor Grids, Ladles, Plungers, Skimmers

Bench Rammers-DISCONTINUED

The problem of rammer breakage with the original aluminum hand rammer has been corrected by using a more ductile analysis of aluminum. The illustration “A” shows the angle of bend the rammers will withstand. Rammer is available with a molded peen end shown in illustration “B”. The 14″ rammer has a molded replaceable peen end.

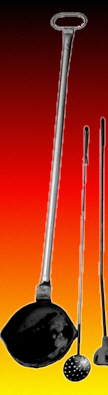

Bell Plunger

Bell Plunger is heavy cast iron. Bell has a 4″ outside diameter (3 1/2″ I.D.) with a approx. 35″ handle. For degassing and deoxidizing molten metal.

Approximate Weight: 4 lbs. Part No. 031630

Available with 6 foot handle. Part No. 031622

Skimmer (all purpose)

Skimmer is 4″ in diameter. Skimmer head is made of stainless steel. Handle is 30″ long. Approximate Weight: 3 lbs. Part No. 031670

Pouring Ladles (For Aluminum Only)

MIFCO pouring ladles (left side of above picture) are low carbon steel with black pipe handles and are available in the following sizes:

| Part No. | Diameter | Cap. of Alum. | Approx. Wt. |

|---|---|---|---|

| 031626 | 7" | 5 lbs. | 11 lbs. |

| 031627 | 8" | 8 lbs. | 15 lbs. |

| 031628 | 9" | 12 lbs. | 19 lbs. |

Tool Kits for Molders Benches- both kits are DISCONTINUED

Plastic hand riddles are available in the online store.

MKB-2 Tool Kit for MB-2 Molders Bench (Part #033550)

| 2 - M-5 Tool Kits | 1 - Parting Dust 10# with Bags |

| 2-Aluminum Rammers | 2 - Molders Shovels (10") |

| 1 - Hand Riddle (18" diameter x #4 mesh) | 2 - Hand Riddles (18" diameter x #8 mesh) |

| 1 - 24" Strike-off Bar |

MKB-1 Tool Kit for MB-1 Molders Bench (Part #033650)

| 1 - M-5 Tool Kit | 1 - Parting Dust 10# with Bags |

| 1 -Aluminum Rammer | 1 - Molders Shovel (10") |

| 1 - Hand Riddle (18" diameter x #4 mesh) | 1 - Hand Riddle (18" diameter x #8 mesh) |

| 1 - 24" Strike-off Bar |

** OIL BONDED Foundry SAND (premixed) . DISCONTINUED

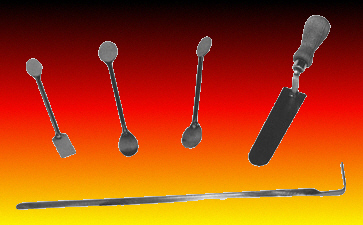

Molders Tool Sets

Set # M-5 (Part Number 031610): DISCONTINUED BY SUPPLIER

One each of the following items:

1″ x 5″ Round Point Trowel

1″ Gate Cutter & Spoon

1″ Slick & Oval

1″ Slick & Square

3/8″ x 14″ Lifter

Set # M-9 (Part Number 031611): DISCONTINUED BY SUPPLIER 01/2022

One each of the following items:

1-1/4″ x 5″ Square Trowel

1″ Gate Cutter & Spoon

1″ Slick & Oval

1″ Slick & Square

1-1/4″ x 5″ Round Point Trowel

1″ Heart & Leaf

1″ Taper & Leaf

3/8″ x 14″ Lifter

3-3/4″ x 14″ Bench Rammer

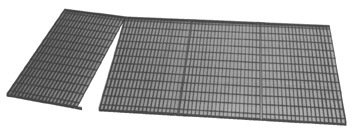

Sectional Grid Pouring Floor

In Safe Foundry Practice, you should not pour into molds which are on a concrete floor. This practice is dangerous because the molten metal spilled on the floor will cause chunks of concrete to blow out of the  floor surface under the molten metal, throwing hot metal and concrete upward onto the operator. If you notice, in foundries, you will never see them pour on anything but dirt floors or over a grid. In most schools, the foundry area seems to be an after thought because there is never a safe pouring area built into the floor. For this reason, the makers of MIFCO furnaces, safety tongs and shanks, have come out with another product to make the foundry safer. The Sectional Steel Grid Pouring Floor is made up of 2′ x 4′ sections that are fastened together. When laid on the floor side by side they give you a pouring floor that is 4′ wide and as long as you want it. The grid floor can be laid in minutes. Spread the sand between the grids and the pouring area is ready for the foundry session whether it is a day, six weeks or a year. When the foundry session is over, just pick up the grids, sweep up the sand and the area is clean again. Another option for the pouring floor is a shallow pit 6″ deep, filled with at least 2 inches of foundry sand and covered at floor level with our steel grids.

floor surface under the molten metal, throwing hot metal and concrete upward onto the operator. If you notice, in foundries, you will never see them pour on anything but dirt floors or over a grid. In most schools, the foundry area seems to be an after thought because there is never a safe pouring area built into the floor. For this reason, the makers of MIFCO furnaces, safety tongs and shanks, have come out with another product to make the foundry safer. The Sectional Steel Grid Pouring Floor is made up of 2′ x 4′ sections that are fastened together. When laid on the floor side by side they give you a pouring floor that is 4′ wide and as long as you want it. The grid floor can be laid in minutes. Spread the sand between the grids and the pouring area is ready for the foundry session whether it is a day, six weeks or a year. When the foundry session is over, just pick up the grids, sweep up the sand and the area is clean again. Another option for the pouring floor is a shallow pit 6″ deep, filled with at least 2 inches of foundry sand and covered at floor level with our steel grids.